Information

What is pumpable concrete?

The concrete mix design must be correctly proportioned so that the concrete will flow easily and uniformly through the pipe. The pipeline diameter should be 3-1/2 to 4 times greater than the maximum aggregate size for pumped concrete. This helps ensure that the pipeline will not become clogged.

Another factor in mix design is the slump of the pumped concrete. A higher slump will cause concrete to flow more readily, making the concrete easier to pump.

However, an excessively high slump can cause the concrete to separate, resulting in plugs in the pump or line.

What makes concrete Pumpable? Pumpable concrete can be pushed under pressure through a pipeline as a cylinder, separate from the pipeline wall by a lubricating layer of water, cement, and sand (mortar). A concrete mix must be such that the concrete can pass through reducers in the pipeline system, and can go around bends in the line. In order to obtain this type of pumpability, the mix must be dense, cohesive, and have sufficient mortar. (Mortar required depends on the line size, efficiency of concrete pump, and pressure available for pumping concrete).

Avoiding Blockages

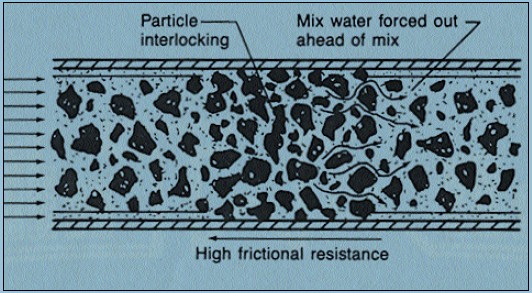

When concrete is pumped, water in the mix transmits the pump pressure to the concrete slug. But if spaces or voids between aggregates are not filled with mortar, or if the mortar is too thin and runny, pump pressures cause segregation, forcing water through the mix. When this happens the lubricating layer is lost, coarse particles interlock, friction i n c re a s e s, and the concrete stops moving.

Normal changes in pipeline diameter or direction cause aggregates in the mix to rearrange their position. Cohesive mixes deform as they go through bends or reducers. But if a mix is harsh or lacks mortar, it doesn’t deform readily and a blockage or plug could occur.

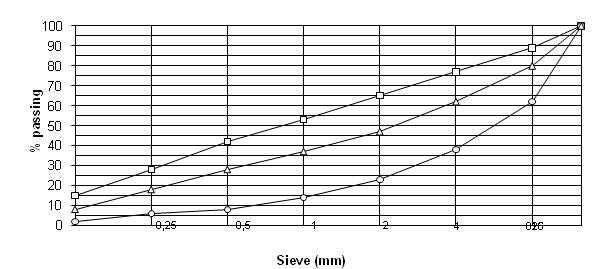

To prevent plugs, the pressure at which segregation occurs must be greater than the pressure needed to pump the concrete. This can be accomplished by filling the spaces between aggregate particles with smaller aggregate. Using a range from coarse to fine reduces the size of the spaces between aggregate particles. Using enough cement or other fine fines in the mortar also helps.

Concrete mixes with too many fines also may be difficult to pump. Here, the problem isn’t segregation. The mix is cohesive but friction between the concrete and the line may be so great that pump pressure isn’t high enough to move the concrete. This pumping problem is more common with high-strength concretes and with concretes containing a high proportion of very fine materials such as rock dust. These concretes are sticky, and additional pressure is needed to overcome adhesion between the mortar and the pipe walls. Increasing the amount of well- graded coarse aggregate in these mixes helps reduce the fines content and improve pumpability. Use of a coarser sand also is recommended.